Horizontal Flowpack Machines(high speed wrappers)are manufactured for the customers, aiming high capacity range with multiple product types. It is designed to meet the most demanding requirements in terms of packaging speed, quality sealing, ease of cleaning and high standarts of the internal and structural compenents.

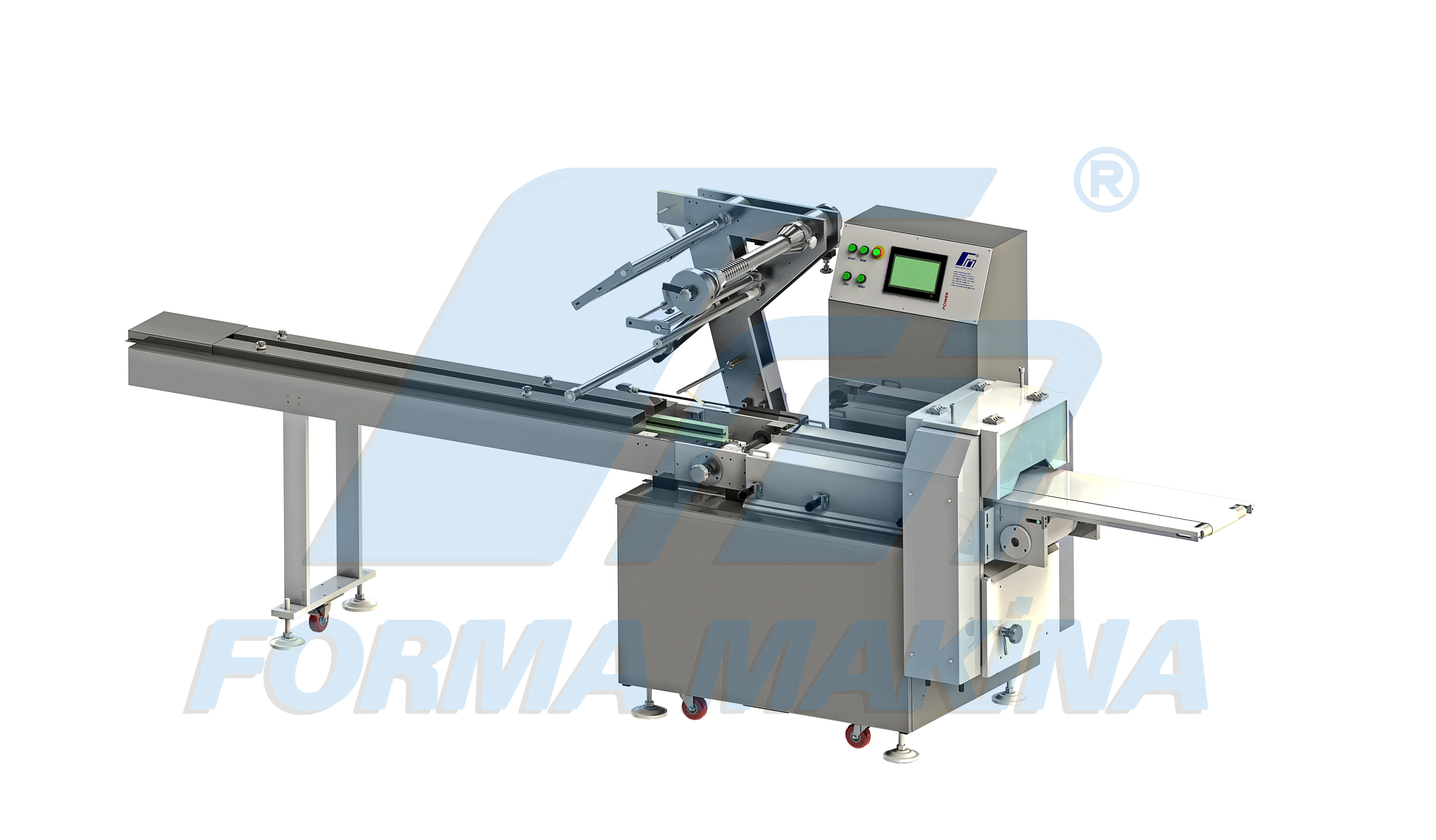

YA-100 model horizontal flowpack machines are produced for the companies which targets a production of multiple varieties with medium capacity figures. These machines can be used mainly for ;

- Food sector : Biscuit, chocolate, wafer, bar, halwa, candy, loukoum, delight, cake, bread, etc.

- Cosmetics and domestic sector : Soap, cleaning tissue and sponges, razor blades, etc.

- Automotive sector : car accessories, spare parts, etc.

Others : medical, electrical, giftware and any plastic material to be wrapped, etc.

and any other similar product. The machine is constructed on a modular aluminum base and equipped with stainless steel enclosures. There are easy change pushers available on the infeed conveyor which allows to pack different types of products.

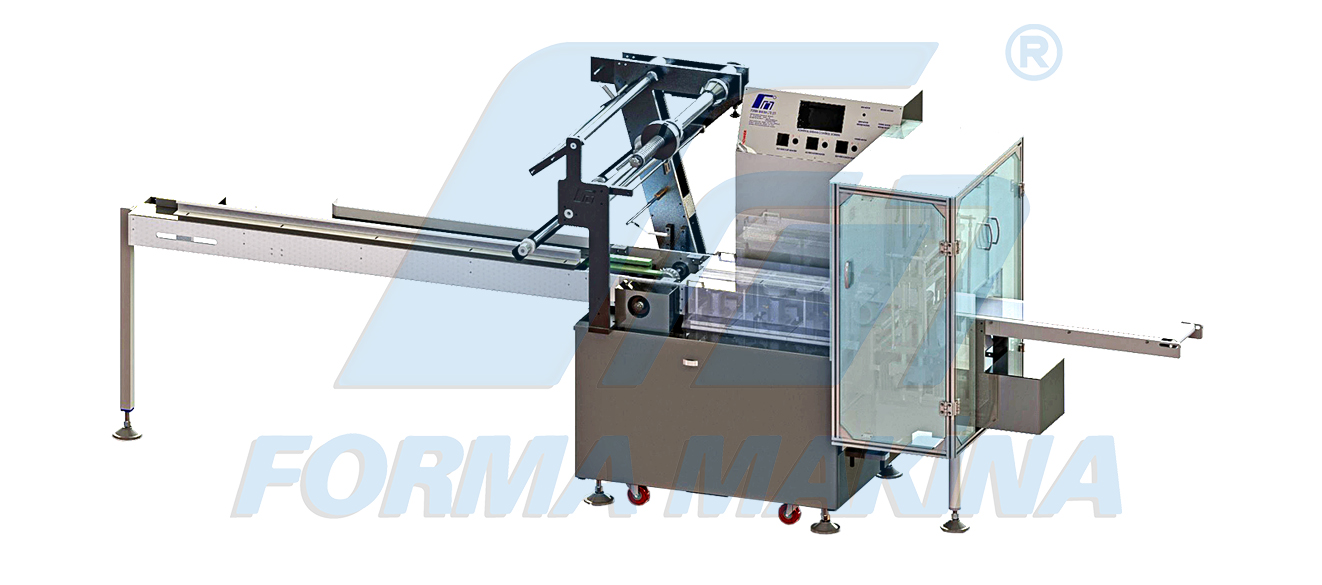

YA-110 model horizontal flowpack machines are produced for the companies which targets a production of multiple varieties with medium capacity figures. The machine is constructed on a modular aluminum base and equipped with stainless steel enclosures. Sealing jaws are designed as "box-motion" type which enables the packing of the higher and taller products. Servo motor driven 3 pairs of longitudinal fin seal wheels are available to control the film flow. Beside a jaw group with pneumatic system that provides noiseless operation and faster suppression regulation, special perforated trim cutters are also available which are adjusted with the piston system and fixed. At hot seal applications it's possible to use the cellophane, pearlize, polypropylene and aluminum laminated materials as in the form of roll and at the cold seal applications It is possible to work with all types of cold seal packaging materials.

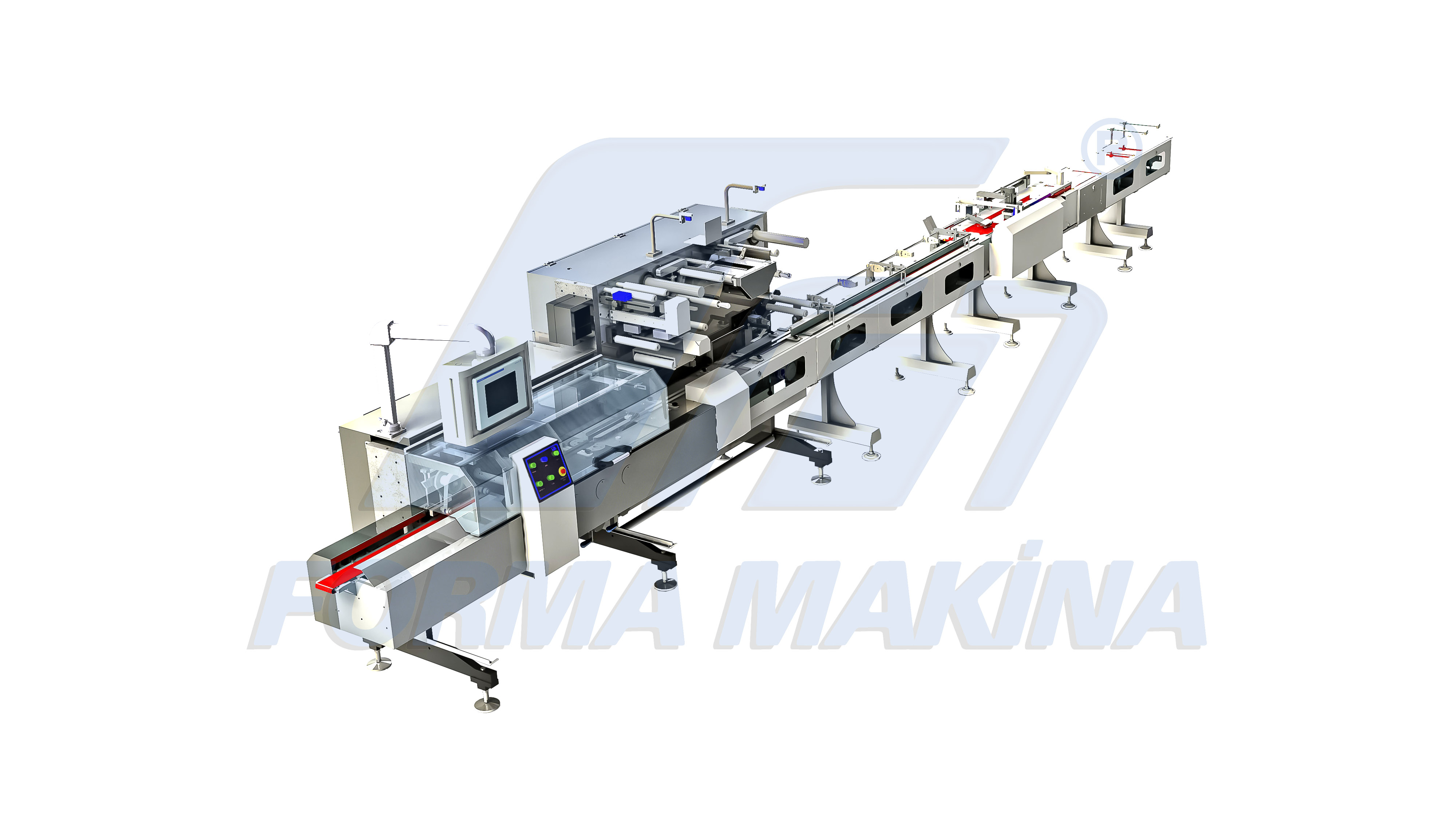

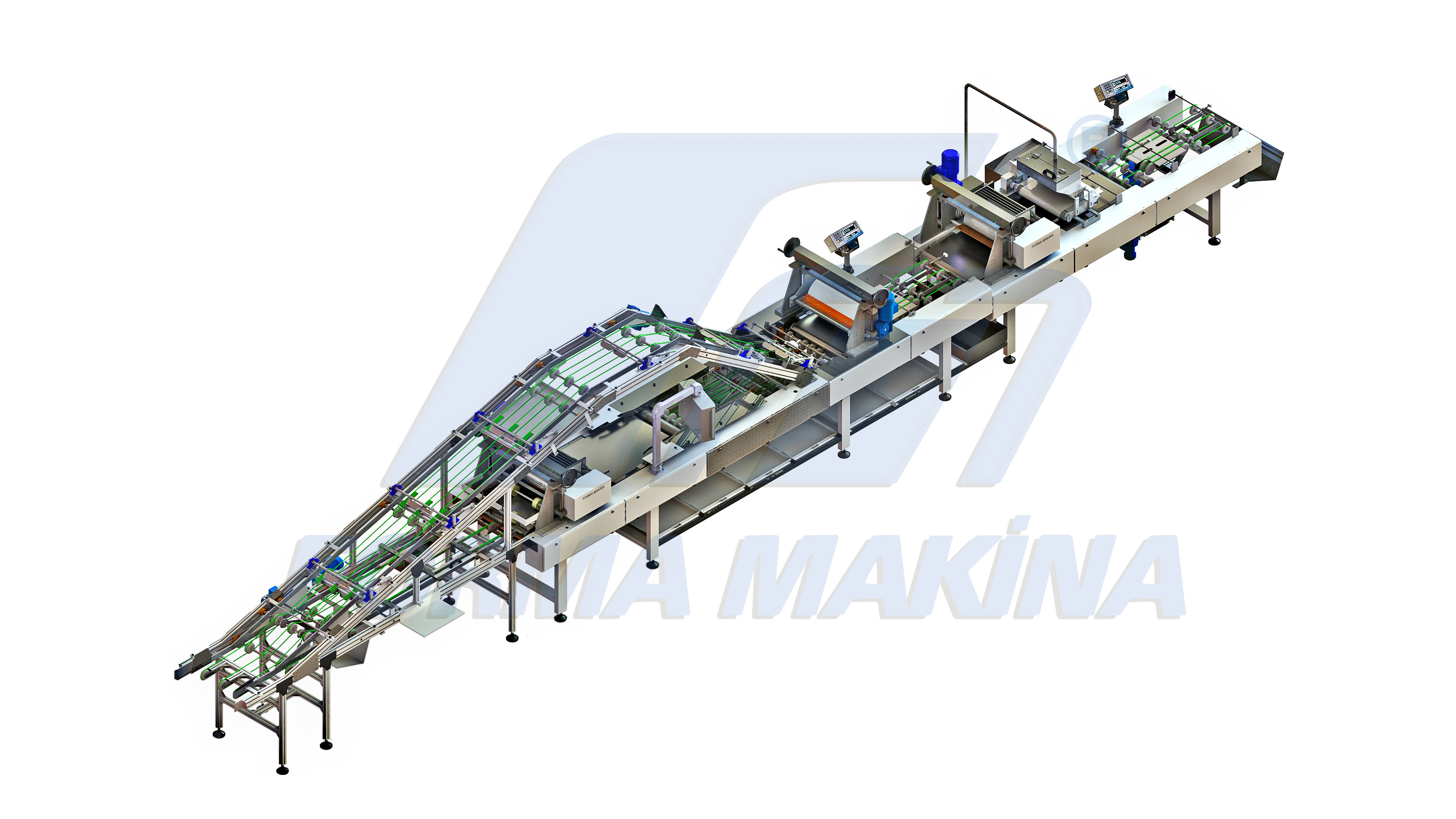

YA-300 model horizontal flowpack machines (high speed wrappers)are manufactured for the customers, aiming high capacity range with multiple product types. It is designed to meet the most demanding requirements in terms of packaging speed, quality sealing, ease of cleaning and high standarts of the internal and structural compenents. Modular cantilevered frame of steel elements. Manufactured and weared by AISI 304 stainless steel components.the machine when guards are openIndividually adjustable film reels provide enhanced film control for tighter packages. Double film reel-holding shaft with servo controlled film extension and brake system. Automatic film splicing system and reel centering control.

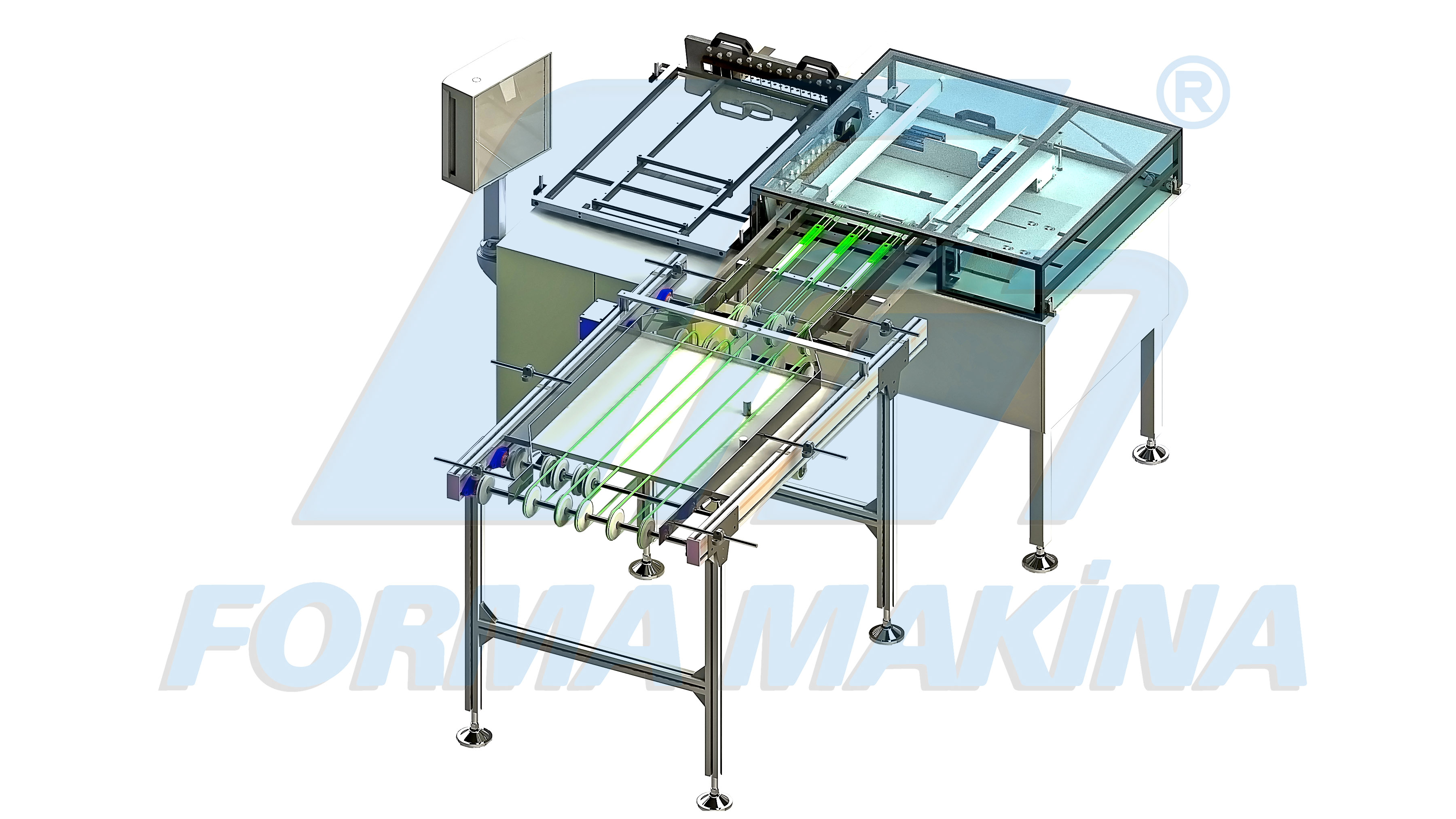

Fully automatic cutting machine for cutting cream filled wafer sandwiches by fixed steel blades or cutting wires. According to the further processing desired, the wafer sandwiches are cut single sandwiches or as sandwich stacks. For cutting, the sandwiches are pushed first through the first cutting frame at the right angles to the first frame. As optional with a special design, a twin cutting machine for high capacities can be supplied. Twin cutting version enables to work with two different wafer dimensions at the same time.

Cream Spreading Machine (KS), applying cream on the baked wafer sheets into blocks and used for the desired floor. Minimum 2-fold between the wafer sheets can be created by applying one layer of cream three-storey blocks. A maximum of 6 times while rubbing cream wafer sheets can be created between the 5th floor of 11-storey block. Block creation system is pneumatic. Driven cream can optionally single color or two colors. Creams expulsion optionally be discharged with or icing on the plate or film system called wafer leaf cream called top contact system is provided with plastering. The cream can be used more efficiently, with machines running simultaneously portable tank under the cream-walled cream recirculation system it is available. Thanks to the cylinder group placed on the floor system is provided homogeneously distributed ironing out the cream. Food is made from 304 stainless steel and compatible dressed. Nuts can be added as an optional Bulk Unit.

Forma Makina is also manufacturing custom made feeding systems providing the solutions meeting customer needs. We are serving the confectionery industry at all times with our highest performance.

Wafer Baking Machine -Wafer Batter Production Plant-Wafer Cutting Machine-Wafer Distribution Device-Wafer Sheet Cooler -Wafer Spreading Machine -Wafer Grinding Machine

Horizontal Flowpack Machines (high speed wrappers)are manufactured for the customers, aiming high capacity range with multiple product types. It is designed to meet the most demanding requirements in terms of packaging speed, quality sealing, ease of cleaning and high standarts of the internal and structural compenents.