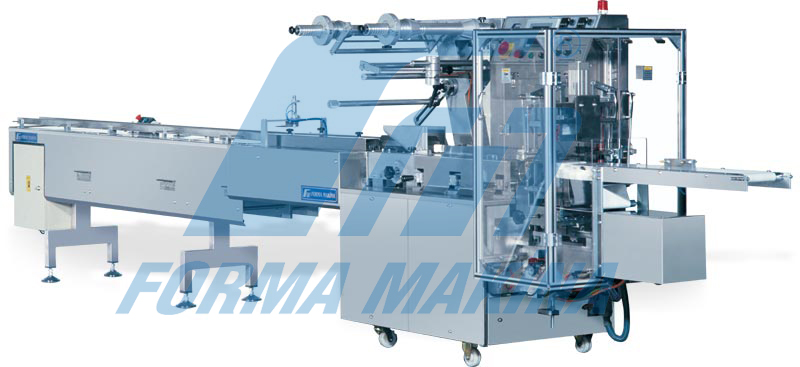

YA-110 model horizontal flowpack machines are produced for the companies which targets a production of multiple varieties with medium capacity figures. The machine is constructed on a modular aluminum base and equipped with stainless steel enclosures. Sealing jaws are designed as "box-motion" type which enables the packing of the higher and taller products. Servo motor driven 3 pairs of longitudinal fin seal wheels are available to control the film flow. Beside a jaw group with pneumatic system that provides noiseless operation and faster suppression regulation, special perforated trim cutters are also available which are adjusted with the piston system and fixed. At hot seal applications it's possible to use the cellophane, pearlize, polypropylene and aluminum laminated materials as in the form of roll and at the cold seal applications It is possible to work with all types of cold seal packaging materials. |

| In order to enable the easy use of the machine, all the necessary facilities are provided on its electrical panel; easy access and setup possibility is enabled via touch screen display for the package length, photocell adjustment, machine speed, etc. To ensure a safe operation, safety switches and special covers are used at the jaw groups. Usual utilization of these machines in food sector is the multipack packaging, wafer blocks (250-500 gr.) and couverture chocolates up to 2500 gr. The average electrical consumption of this machine, which has a speed up to 40 package per minute*, is approximately 4,6 kW. * The speed varies according to the product dimensions (width, length, height), product form, the way of its exit from the production line and the thickness of the film. |

| SPECIFICATIONS | YA-110 |

|---|---|

| WIDTH | 1250 mm |

| LENGTH | 5500 mm |

| HEIGHT | 1600 mm |

| WEIGHT | 850 kg |

| ELECTRICAL CONSUMPTION | 4,6 kW |

| CAPACITY (HOT HEALING) | max 40 pcs/min |

| CAPACITY (COLD HEALING) | max 40 pcs/min |

| PACKAGE WIDTH | min 15 mm - max 200 mm |

| PACKAGE LENGTH | min 40 mm - max 500 mm |

| PACKAGE HEIGHT | min 2 mm - max 100 mm |